REIRODORU (Fabric model HF 102) has made its debut in September 2017 as the world's first HDR compliant screen, and has penetrated the home theater market with amazing speed. So I would like to tell the story behind REIRODORU's development to the home theater fans in three times. The first is

the story of Pure Mat which became the base of the fabric.

REIRODORU (Fabric model HF 102) has made its debut in September 2017 as the world's first HDR compliant screen, and has penetrated the home theater market with amazing speed. So I would like to tell the story behind REIRODORU's development to the home theater fans in three times. The first is

the story of Pure Mat which became the base of the fabric.

It is the history of Pure Matt that flows to the base of development of REIRODORU (HF 102). The origin of Pure Mat who showed prototype fabric to the projector officials is the starting point of further development in 2000, exclusive devotion to “Screen Gain” was the interpretation of screens at the time but we propose a new way of thinking as "Diffusion type fabric" which was homogeneous image quality can be reproduced as a reference.

Nowadays, white mat(diffusion type) keeps over 80% of the sale of the screen, but at the time the brightness of the projector was not enough, eyes tended to get into the high gain screen by all means.

Pure Mat 101 (WF 101) is developed focusing on the fabric which is the origin of the fabric in the market needs. The evaluation at that time was a favorable thing dark, but screen responds obediently to the adjustment of the projector.

From that point on, development for commercialization spurred, on 2002 gray back Pure Mat II (WF 201), 2004 Blackback Pure Mat II Plus (WF 202) was born, and it is still remembering that the market recognized it. The development of Pure Mat after that has evolved to the Pure Mat Ⅱ EX (WF 203) with surface finish to 2010 Full HD.

And quickly responding to the market introduction of the 4K projector, Pure Mat III (WF301) was born, but please read "Dr. Ichino’ s monologue" or "WF301 Development Story" for details of the development story so far.

For Pure Mat, the OS corporation's obsession to the screen and the history of fabric development are condensed. Whenever video technology evolves from 4K to HDR, 8K, it returns to the technical origin.

The 4K compatible screen pure mat III (WF301) released in 2013 has halved the thickness of threads used up to WF 203. Because of the thinness of the thread, the usable product was only a fixed type screen (PA). In 2014 the next year Pure Mat III Cinema (WF 302) corresponding to the roll-up screen was announced. WF302 is still the finest 4K compatible screen. Its exquisite screen surface boasts a finish that fully corresponds to 8K.

However, the following technologies have already been announced at that time. It is the recommendation HDR (High Dynamic Range) of the International Telecommunications Union of 2012. At the beginning, I did not understand even the meaning of the abbreviation as HDR, but apart from that, the issue of the next generation of pure mat was already being debated from the early development stage of WF 302.

However, the following technologies have already been announced at that time. It is the recommendation HDR (High Dynamic Range) of the International Telecommunications Union of 2012. At the beginning, I did not understand even the meaning of the abbreviation as HDR, but apart from that, the issue of the next generation of pure mat was already being debated from the early development stage of WF 302.

When full HD comes up 80 inches was standard as the screen became 100 inch standard, with the introduction of 4K 120 inch would be the standard. At that time, luminance correction is required. Pure Mat III Cinema (WF 302) has achieved a maximum gain of 1.0 on the mat screen as a result. Based on this technology we have been exploring the development of the next HDR screen.

The development points are diverse even though we say screen development to put into a few words.

The development points are diverse even though we say screen development to put into a few words.

The ultimate pure mat WF 302 which was born as a result of clearing all these points. It is the finest fully diffusing screen. Regarding the development of HDR, wide range of technologies is used which has been accumulated over the past year’ s experiences. Therefore, we were able to narrow down the development task of HDR to one.

The basics of screen development are the same in HDR. But the goal I want to accomplish is only one "from light to lighter, from dark to darker", yet it is a very difficult task.

The basics of screen development are the same in HDR. But the goal I want to accomplish is only one "from light to lighter, from dark to darker", yet it is a very difficult task.

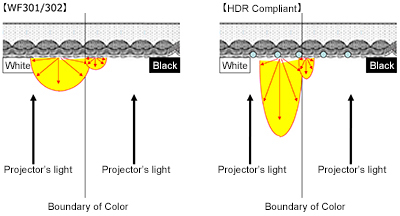

On the screen that received the light of the projector, black portions (little amount of light) and other colors (large amount of light) exist simultaneously, black intervenes to other colors, other colors interfere with each other, The color boundary becomes ambiguous. In order to put the fine and wide gradation expression of HDR into practice, we needed to find the way to reduce the influence of stray light and harmful light more than the screen up to now. The development team had to go back to the high gain screen myth and verify it again.

Why did we need Pure Mat? Why did we aim to escape from the high gain screen? The high-gain screen at the time was for compensating the light intensity of the projector. (Even now, the beads screen is a screen that is often used for similar purposes.) Therefore, it seems that the poor color balance and some brightness unevenness such as hot spots were put as secondary priority. So the challenge to fabric started with the theme of homogeneous image reproduction.

Fortunately the special double woven WF 302 in the 6th generation realized a very fine finish. By using this fabric as base it was able to display 4K pixels perfectly. It was also possible to judge that the fine color gamut of BT 2020 of 4K video and wide gradation expression of HDR will be possible. Increasing the gain increases the reproducibility of bright scenes and prevents stray light, thereby deepening the dark tone obtained broad tone in plus or minus . That means that we had to solve the evaluation of the high gain screen at the time. Because we thought that we needed reflectance of 1.0 or more for HDR reproduction.

"The bright part is brighter and the darker part is darker", so we have to realize the opposite properties optically on the same material, so we decided to first work on coating the screen surface to raise the gain.

The thing that should not be forgotten is that it preserves the characteristics of diffusion type so as not to damage the original image quality of Pure Mat. There are disadvantages and advantages for the reflection characteristics (diffusion type, regression type, reflection type) of existing screens respectively. We tend to focus on improving the disadvantages in the development process, but in this development we changed our mindset. We thought that complementing each other's disadvantages by incorporating all the merits of the reflection characteristics of existing screen fabrics, and we can realize a wide range of gradation expression and fine color gamut. For that reason, we tried prototyping to decide material selection and formulation of the coating material.

For high gain realization, regression type and reflection type characteristics contributed to a certain extent, but it was the splendor of the material of pure matte that the development team reaffirmed. Even the development staff who are familiar with Pure Mat was very much surprised at securing a wide viewing angle that contributed greatly to fine image reproduction.

While repeating prototyping, the evaluation at the time of seeing the prototype fabric of 2012 by 3 commentator was very helpful. Test data at the time of pure mat Ⅲ development became a big hint of HDR development. In order to realize reduction of hot spot which tends to be high gain without killing the characteristics of pure mat due to incorporation of beads and pearls, it seems to be a point to utilize two different properties of bead type and pearl type.

While repeating prototyping, the evaluation at the time of seeing the prototype fabric of 2012 by 3 commentator was very helpful. Test data at the time of pure mat Ⅲ development became a big hint of HDR development. In order to realize reduction of hot spot which tends to be high gain without killing the characteristics of pure mat due to incorporation of beads and pearls, it seems to be a point to utilize two different properties of bead type and pearl type.

Technically, applying a special coating to Pure Mat III based fabric made it possible to have the characteristics of reflective type and regression type at the same time on one screen surface while taking advantage of the characteristics of diffusion type.

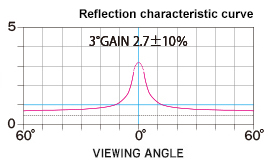

When accumulating from the prototype test of 2012 it will be five years have passed. Finally, with a high gain, relatively strong reflection characteristics are obtained even for harmful light, and if it is a viewing position in the screen, you can see good HDR characteristics that can not be imagined from the reflection characteristic curve. Moreover, we were able to secure the characteristics that enjoy pure matte image quality even at field angle outside the screen.

The bright part becomes brighter by raising the gain. However, with a simple high gain screen, a hot spot emerges and a large difference appears in the brightness near the optical axis and the periphery of the screen. However, by placing diffusive properties there, it is possible to prevent extreme loss of gain.

The bright part becomes brighter by raising the gain. However, with a simple high gain screen, a hot spot emerges and a large difference appears in the brightness near the optical axis and the periphery of the screen. However, by placing diffusive properties there, it is possible to prevent extreme loss of gain.

The black part is hardly affected by the bright part due to the characteristic like the regression type that prevents reflection of light from mixing as much as possible at the boundary between adjacent bright parts. As a result, black can be expressed more black. From another point of view, it means that not only lightness but also color purity will be high.

The reason for naming wide gradation type is that the contrast ratio increases with the coexistence of these different reflection characteristics, and the color gradation becomes very wide. It became a screen that can reflect the characteristics of each HDR projector as it is.

Why does the HF 102 have a gain of 2.7?

Why does the HF 102 have a gain of 2.7?

Gain = Increasing brightness can be done relatively easily technically. In addition, it is said that high brightness is necessary to fully draw out the HDR function of the projector. However, we have commercialized it with a gain of 2.7. The reason is that the limit of being able to enjoy images of the same reflective type as the side of the screen without generating hot spots is 2.7. As a result, uniformity of the entire screen was born, which can not be thought of as a drop in the gain of the reflection characteristic curve.

REIRODORU was selected as a screen for shootout by the HDR projector of three manufacturers at an appropriate timing. It took over half a year to prepare. A moment came in June 2017 when a video was released to 120-inch REIRODORU from each company's HDR projector after having undergone four or more stakeholder meetings.

First of all, I did HDR technical explanation using Pure Mat III Cinema (WF 302) with a gain of 1.0 which I pride ourself as the highest peak of the 4K screen. After that, screening of movie contents by HF 101 (gain of 2.7) (REIRODORU name was not yet there) was performed. As the result, the common comment received from every projector maker was the word "Hot Spot is not visible, but HDR feeling is good" even though it is high gain.

Based on this result, HF 102 was brushed up as a mass production product and REIRODORU was born.

The 4K compatible WF302 is a product that has been refined without changing the diffusion type properties of existing Pure Mat, and is of course also compatible with 2K as an almighty screen. REIRODORU (HF 102) is a product that we made specialized for the purpose of maximizing the characteristics of the HDR projector according to the HDR standard.

As a result, we were able to acquire a completely new reflection characteristic of a wide gradation type REIRODORU's naming also has the thought of development. It is a made-up word that IRODORU of Japanese was superimposed on RE of RESOLUSION. The meaning of resolving power that produces deep coloring was put in it.

REIRODORU is a very delicate product that carries out the coating work one by one after receiving your order. For that reason, we are not only developing coating materials, but also machine manufacturing using coating equipment. In the conventional method of spraying by the hand of a person, it is difficult to uniformly finish the state of the surface uniformly. In that way there will be more parts left to the craftsman's sense and experience.

Continuing to supply stable quality screens is an important point as a long-established manufacturer of screens, and as a result, it was concluded that there is no other way than coating with a machine. However, it was not possible to handle it with general-purpose coating equipment, and we decided to begin with the design of coating equipment. Regarding the mechanization of the coating, I was struggling to reconfigure the conditions for replacing the conditions established by manual prototyping with mechanical work.

As a result, although it is necessary to fine-tune the condition, we knew in advance that machining can be done more uniformly than manual work. However, I am surprised again that it can process more uniformly than expected.

By being able to process uniformly, the quality can be stabilized, and in addition to reducing the number of mechanization steps, it can lead to a reduction in the amount of coating material used. As a result, I think that it can lead to price stabilization. For your world’ s only one home theater, by all means, please try REIRODORU as a rally of our technology.